Established in 1973,

Campbell faithfully serves

the manufacturing industry

all over the world.

Engineer

- Expert inspection services

- Digital diagnosis services

- Reverse engineering

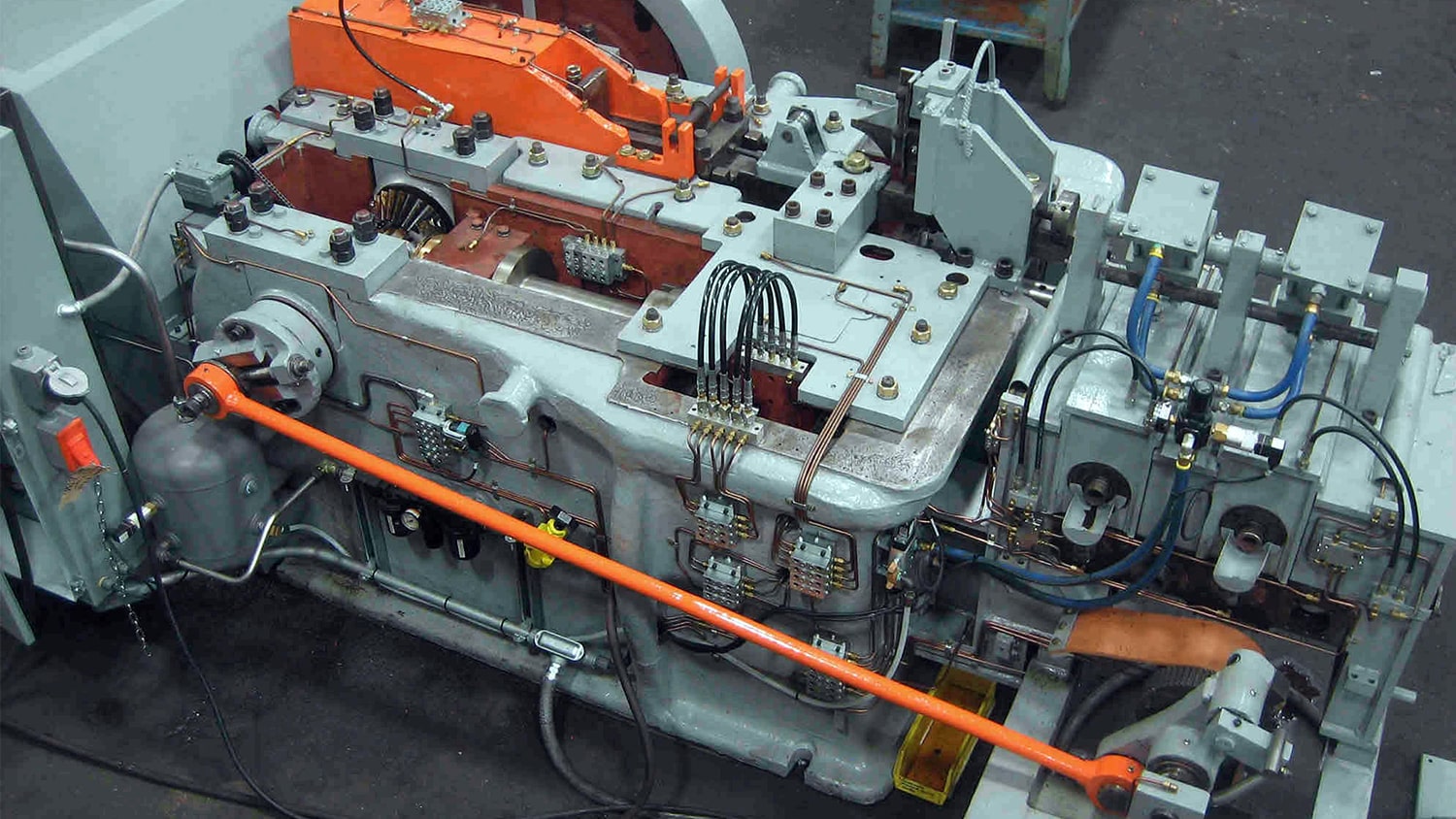

Repair

- Field service

- TPM – Preventative Maintenance service

- Repair worn, damaged, or broken parts

- Manufacture new replacement parts

Rebuild

- Restore equipment to OEM specs

- Update controls + Automation

- Provide used equipment

Used Presses

- Determining the best solution for your operating budget

- Reducing lead time for press replacement

- Retaining the same machine make and model for your plant

New FICEP Presses

- World-class forging technology

- Energy efficient automated machines

- OEM Remote support